The 2-Minute Rule for forklift lights safety

The 2-Minute Rule for forklift lights safety

Blog Article

Forklift strobe lights are an important addition to your forklift. The strobe light-weight mounted on the top of your mast makes the truck very easily noticeable to other cars in minimal-gentle ailments.

Welcome to our thorough manual about the job of blue lights on forklifts and their impact on place of work safety.

Longterm dependability - Influence/corrosion-resistant polycarbonate lens and sealed housing for challenging industrial environments

While forklifts normally operate in a reasonable pace, they could at times speed up when not carrying any masses. This unexpected rise in speed causes it to be difficult for devices to come to an abrupt halt when they experience a pedestrian of their surroundings.

The front wheels on a vehicle or truck steer the auto. Nonetheless, forklifts have steering wheels during the rear, so that they swing around the entrance wheels supporting the load. As a result, the back again close swings vast in the event the forklift turns,

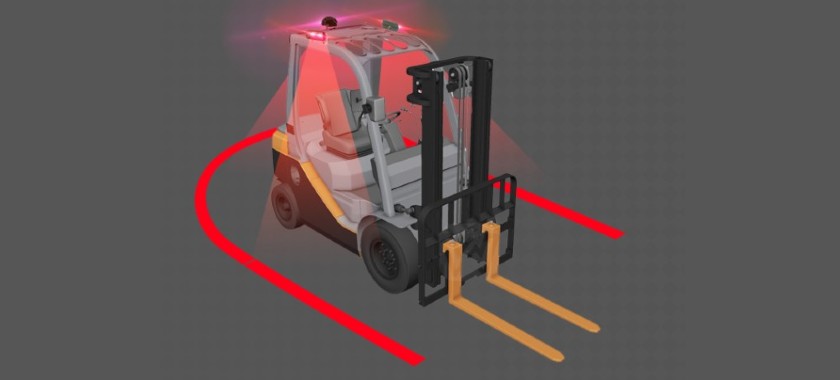

DON’T make your red halo zone far too little. The 2-5 foot halo zone outside the forklift is usually set too little for your vast, rear-conclude swing.

Actions like complete coaching, devices servicing, crystal clear signage, Secure pace boundaries, and safety audits add into a safe workplace. Ongoing enhancement and ongoing schooling retain safety for a best precedence, preserving personnel informed about forklift operation threats.

Enrolling in education equips the operators Along with the awareness and competencies needed to operate forklifts properly.

In contrast to conventional bulbs that require heat-up time, LED lamps present immediate brightness. With LEDs, operators have immediate visibility in the event the forklift commences or when transitioning among locations with different lights problems.

Heavy obligation zip ties keep the lights firmly to the overhead guard. The Purple Zone lights are then adjusted With all the swiveling mounting bracket to the distance of alternative. Every enterprise can set their own individual NO GO ZONE or HALO ZONE forklift lights safety distance, typically among two and 5 toes within the forklift. Installation of each mild bracket need to acquire only a couple of minutes on most can make and products of forklifts. Once all of the lights are mounted, a professional upkeep man or woman or forklift lights safety forklift technician can wire the lights in the forklift’s ability. Exactly where by to attach into your truck’s ability will depend on each make and model, see your neighborhood supplier or contact the manufacturer forklift lights safety Should you have any issues on how to attach them. You may want the Purple Zone lights for being on on a regular basis the forklift is on, even if it's stopped; when forklift lights safety the forklift is shut off, the Pink Zone lights also needs to convert off. If wiring them into electrical forklifts with regenerative braking, ensure you are connected to a circuit that won't expose the lights to substantial electricity surges, This might harm them and wouldn't be lined below warranty.

We've been licensed sellers for many globe renowned forklift spare component brand names to cater to distinct demands.

Presently the Red Zone lights are UL rated for regular kinds of forklifts in addition to EE and LPS rated forklifts. This implies they are able to go on any typical forklift as well as forklift lights safety on EE and LPS forklifts, but not on EX rated forklifts. They won't ever be rated for EX vehicles Utilized in really large hazard places.

Installing safety lights on your own forklift prices a whole whole lot less than an OSHA violation, so it actually pays so as to add both blue and crimson lights on your forklift.

OSHA's normal states: wherever suitable on the worksite, equip vans with extra audio-developing or Visible (such as lights or blinkers) gadgets